What’s FDM 3D Printing Service China?

FDM (Fused Deposition Modeling) is a melting deposition molding process, this 3D Printing service China technology is developed by American scholar Scott Crump in 1988.

The working process of FDM is to melt the material into liquid state at high temperature, extrude it through the print head, then solidify it, and finally arrange it in the three-dimensional space to form solid objects.

How Does the FDM 3D Printing Service China works?

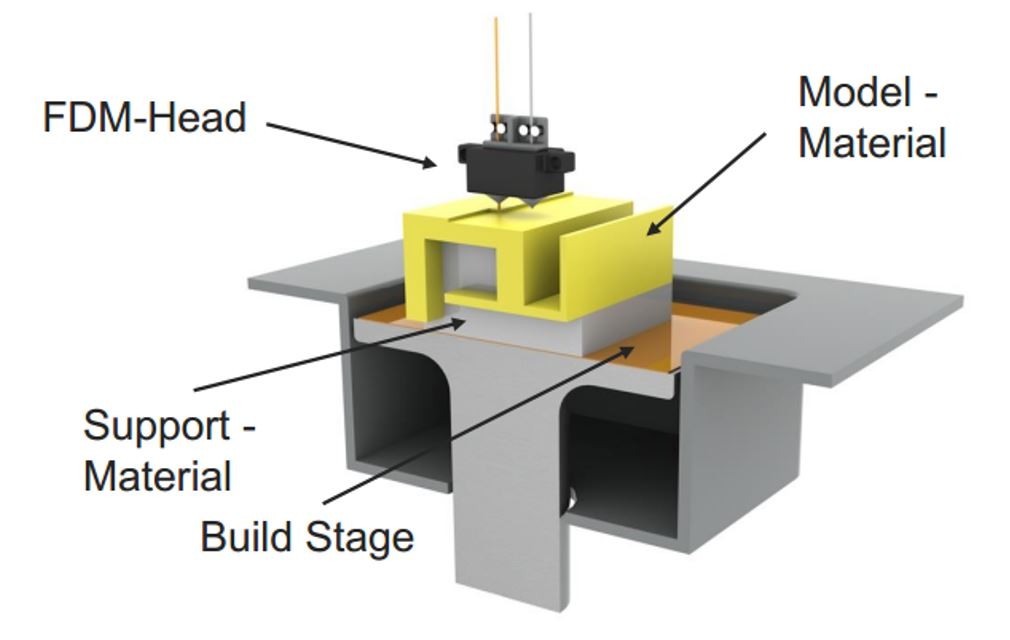

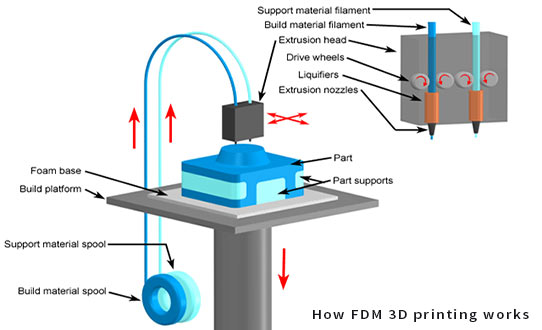

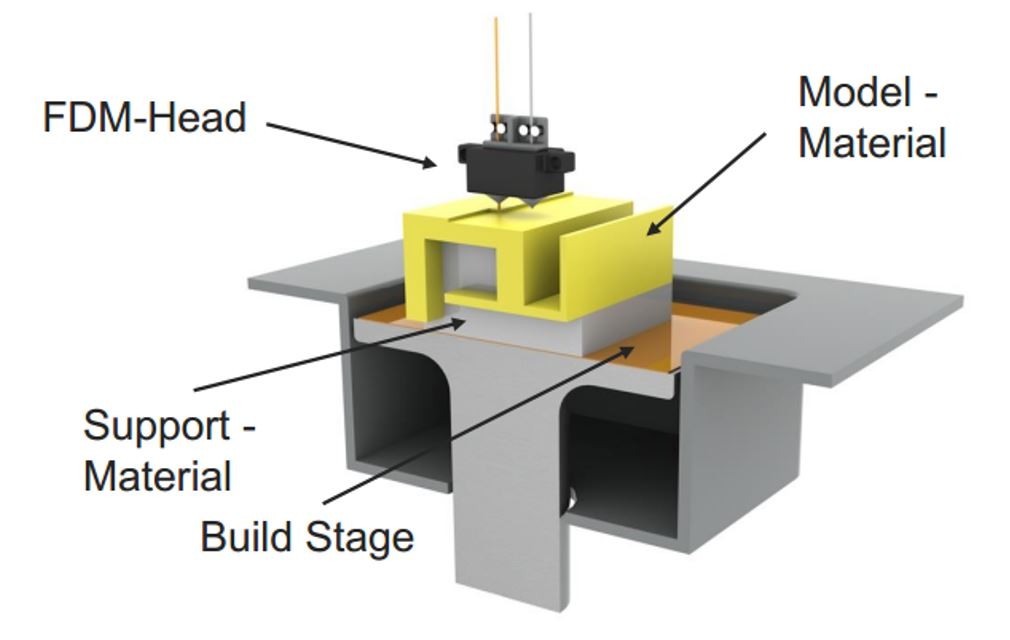

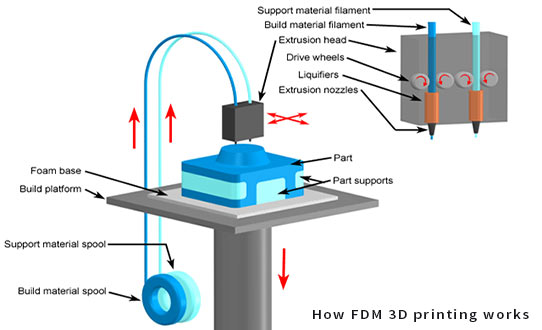

FDM mechanical system mainly consists of five parts: sprinkler head, wire feeding mechanism, motion mechanism, heating studio and working table. As it shows in below picture.

In order to let you have a better understanding on how FDM SLA 3D Printing service works, please see below picture:

Let's see the material of FDM 3D Printing Service China

FDM 3D Printing service China technology can be printed with a variety of materials, such as a variety of composite engineering plastics, nylon plastics with high toughness, etc. But for the desktop China 3D printer that adopts FDM technology, ABS and PLA is the main material.

Type 1 : Engineering plastic PLA&ABS

ABS has excellent comprehensive performance, strength, flexibility, machining performance and higher heat resistance. It is the preferred plastic for making construction machinery parts.

PLA has a wider appliance in desktop 3D printer SLA. PLA plastic is a biodegradable material, which produces a smell like candy during the printing process. Moreover, PLA plastic has a stronger viscosity than ABS plastic after heating, and almost no shrinkage and deformation. Therefore, there is usually no need to heat the printing base plate when printing PLA material.

Type 2 : Flexible plastic TPE&TPU

In business applications, TPE is commonly used in the production of automobile parts, household appliances, medical supplies, shoe soles, smartphone covers, wristbands, etc. Flexible materials TPE, especially polyurethane TPU, can be used to make objects with particularly good extensivity. However, it is difficult to print, especially for remote feeding 3D Printing service China, it is difficult to control the advance and retreat of flexible materials.

Some Main Factors to be considered in FDM China 3D Printer SLA

#1 Printer parameters

The manufacturing and assembly accuracy of 3D printer SLA and the vibration in the working process will affect its printing accuracy.

#2 Infill and Layer thickness

The thickness of the slice will produce visible step texture on the surface of formed product, which will affect the dimensional error of the formed entity and roughness of the surface.

#3 Temperature

The temperature of the nozzle determines the bonding performance of the material. If the temperature is too low, the viscosity of the material increases, and the extrusion speed is slow. Too high, viscosity coefficient reduced, liquidity enhancement, extrusion too fast.

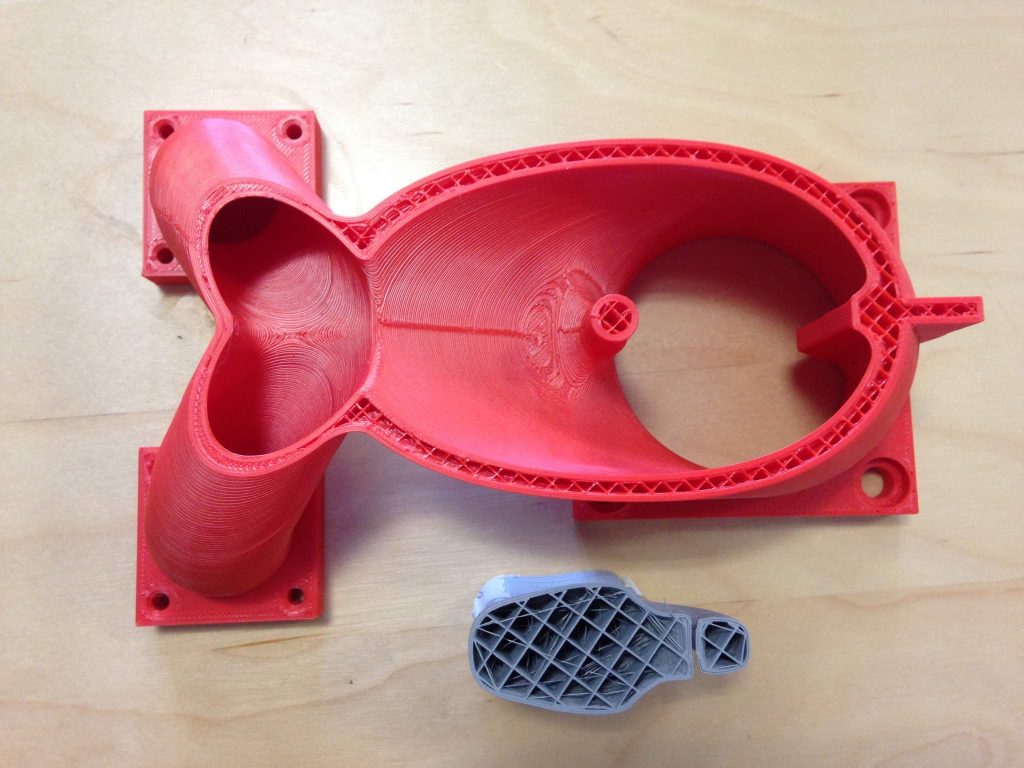

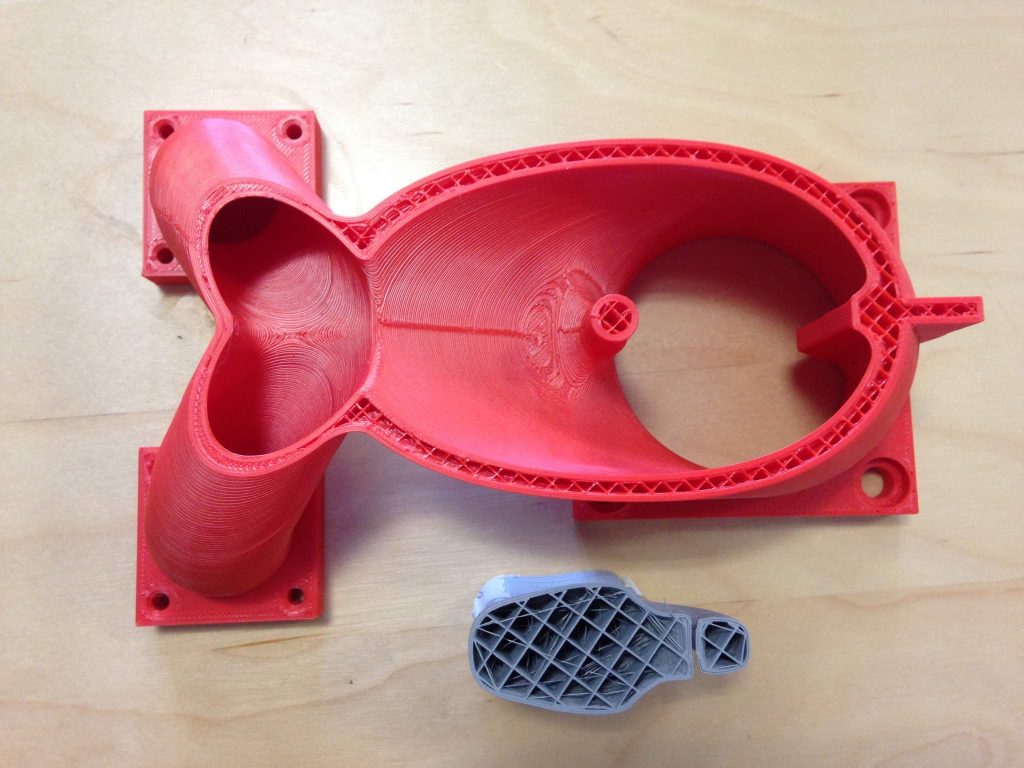

#4 Finishing

Usually the surface is a little rough after printed, then it needs some post-treatment to get better appearance. Sanding and polishing are the most common methods to get a smooth surface. Also, the support material needs to be removed by submerging the finished print in water or using a special solvent to melt away the support material.

What are the advantages of FDM 3D Printing Service China?

1) Low cost

The liquidizer is used to replace the laser in molten deposition modeling technology, and the equipment cost is low. In addition, the utilization efficiency of raw materials is high and there is no pollution by poisonous gas or chemical substances, which greatly reduces the cost of forming.

2) Eco-friendly

FDM system is non-toxic and does not produce peculiar smell, dust, noise and other pollution. No cost to establish and maintain a dedicated site, suitable for office design environment.

3) Simple support removal

The use of water-soluble supporting materials makes the removal of scaffold structure simple and easy, and can quickly build complex inner cavities, hollow parts and assembly structures formed in a single formation.

4) Varieties of plastic materials

Such as engineering plastic ABS, PC, PPS and medical ABS of various colors.

5) Low deformability

The raw materials have no chemical changes during the forming process. The material has good strength and toughness and can be assembled for functional test.

Are you interested in FDM 3D Printing service China technology? Do you have some parts need to be printed? Feel free to send your files to us enquiry@nice-rapidtooling.com to get free quote. We will get back to you ASAP.

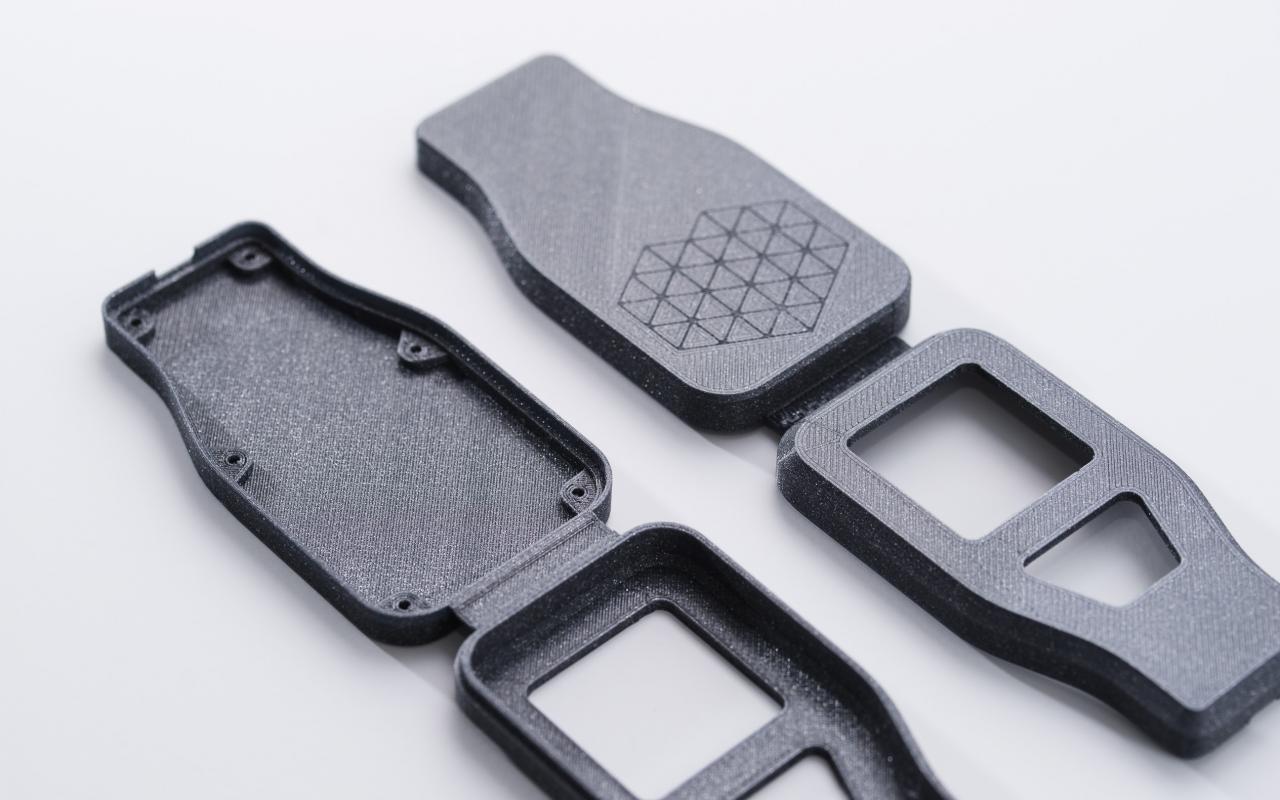

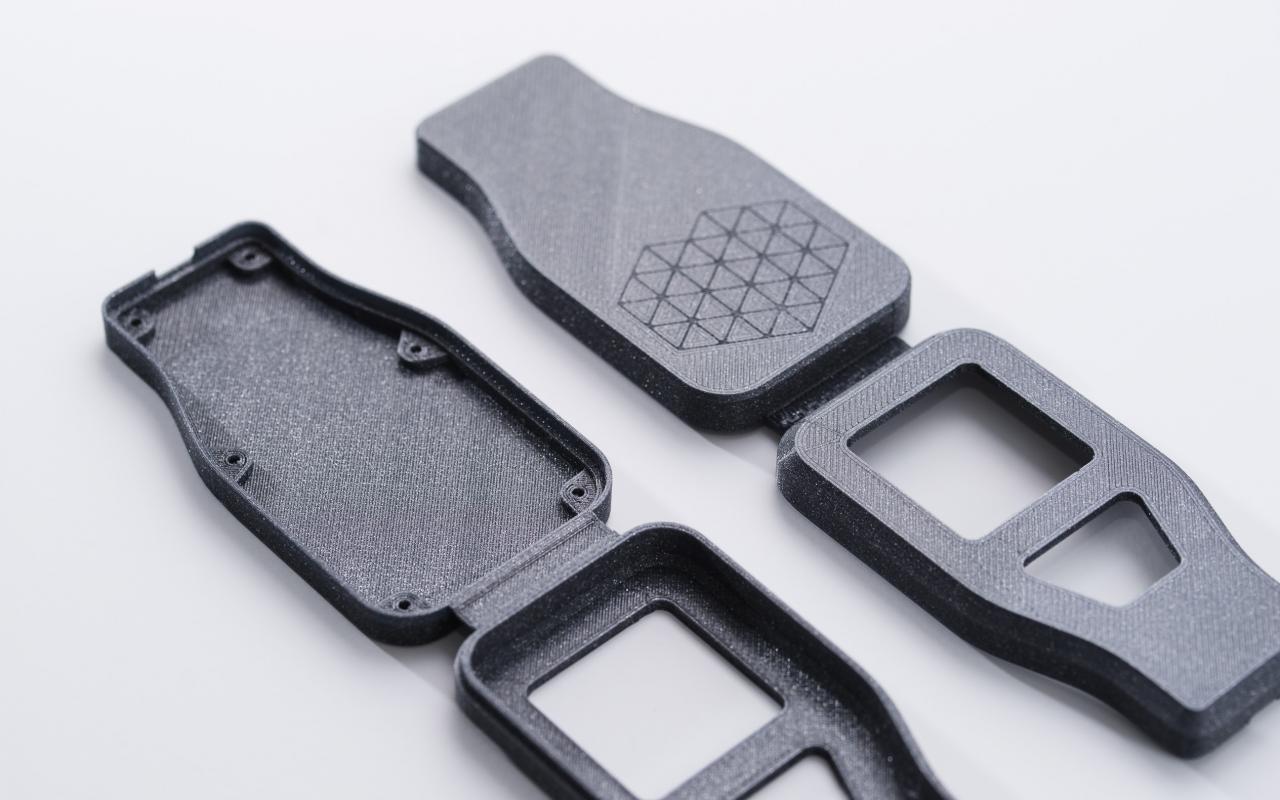

Product display