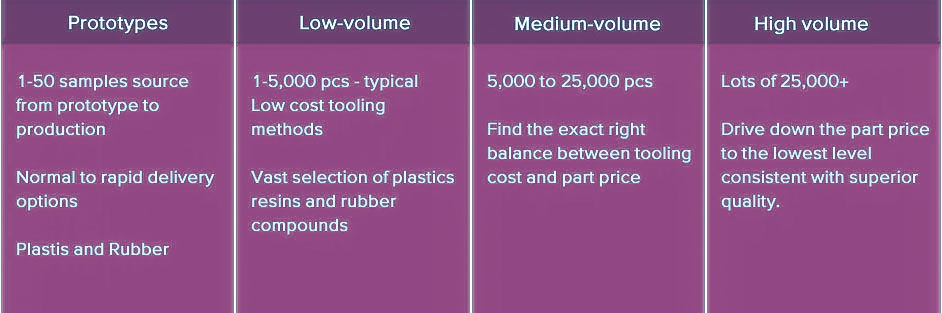

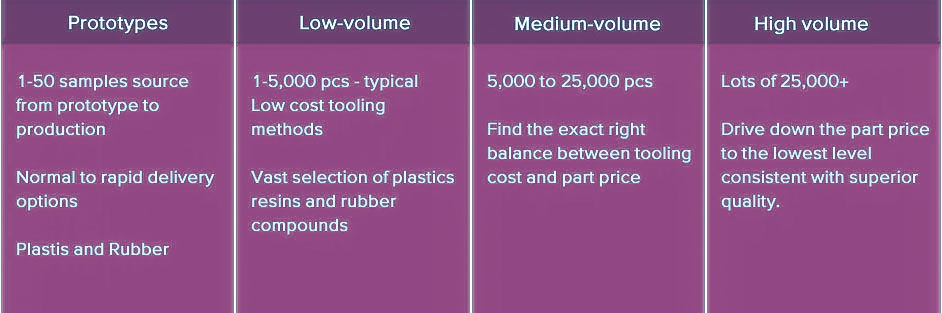

We make low to

medium volume production in plastics, metals and silicones uniquely affordable.

If you are looking for low to medium runs,

then you have come to the right place! Our inexpensive rapid tooling for runs up to 100,000+ injection moulding parts may be exactly what you need. We continually

invest in the latest equipment and rapid manufacturing technology and this, combined with our experienced staff, means that we are well equipped to handle low to

medium-volume production programs.

Low volume production of injection moulded parts is ideal for a few hundred up to thousands of parts of varying complexity. NICE Rapid’s affordable rapid aluminium tooling or soft-tool steel tooling, makes it the most cost-effective method for this type of demand.

NICE Rapid minimises the “cost of waiting” for your

full production tooling run and enables you to get to market quicker by having

an aluminum or soft steel tool made within 3-30 days, (depending on product

complexity and tool functionality).

Test your manufacturing or assembly processes with a pilot run prior to mass production to save time and money!

For high-quantity production, the initial investment spreads across the parts. For low-quantity production, though, capital investment can overwhelm the part cost. There is a balancing act among desired features, cost, and speed. Using commercial off-the-shelf parts in low volume production limit aesthetics and creativity.

Designing complex products for low volume production usually requires compromise. By understanding the limitations of each process, an engineer can tailor designs to make great parts with low-volume techniques. In addition, a designer can amplify the part count by making the left and right sides the same or by using the same part in multiple places. The principles of design for manufacture extend to all processes.

Low volume production methods are typically faster, which allows companies to get their product to market quickly. For manufacturers, efficiency is paramount, and it's important to know which process makes the most sense for each part. Here are a few manufacturing methods that are commonly used for small-volume production.

If you are looking for a low volume production service supplier, you've likely looked in China. There, expansive infrastructure, government support and competitive rates have contributed to an extensive array of production suppliers. However, not all suppliers in China are the exact same. To find the right one for your needs, you'll want to consider several factors. In this guide,Nice Rapid low volume production service team covers 4 great ways to find the right Chinese supplier. Read our post to make the right choice in China. We've also worked closely with companies to improve their designs through our low volume production service and scale their products for larger production runs. We've put together several tips for moving your product from prototyping to production so you can take the next step with our expert guidance.

Our low volume production service team discusses the different types of exoskeletons (including both powered and unpowered models), their many benefits and the major ways they can change industries ranging from construction to healthcare. If you have a low to medium-volume requirement, please contact our expert team: enquiry@nice-rapidtooling.com or contact us using the form on this website or call us at +86 760 8996 2989 for a fast quote and advice.