Light curing molding technology-SLA

Light-curing molding technology (SLA) mainly uses photosensitive resin as raw material, and utilizes the characteristic that liquid photosensitive resin will quickly cure under ultraviolet laser beam irradiation.

SLA focuses on the surface of the photocurable material by using ultraviolet light of a specific wavelength and intensity,

and solidifies it sequentially from point to line and line to surface, thereby completing the drawing of a layered cross-section.

Advantages of SLA process:

01. SLA can produce parts with high dimensional accuracy and complex details.

02. SLA parts have a very smooth surface finish, making it ideal for visual prototypes.

03. Special SLA materials can be used, such as transparent, flexible and castable resin.

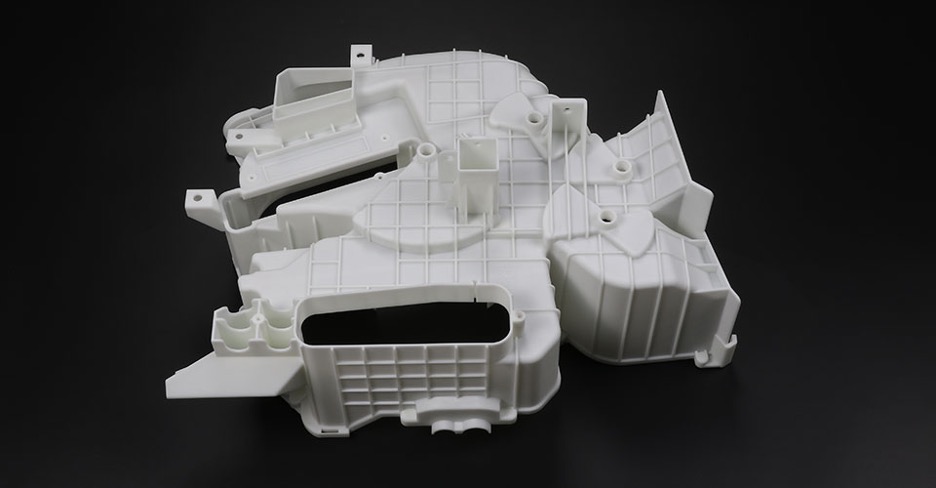

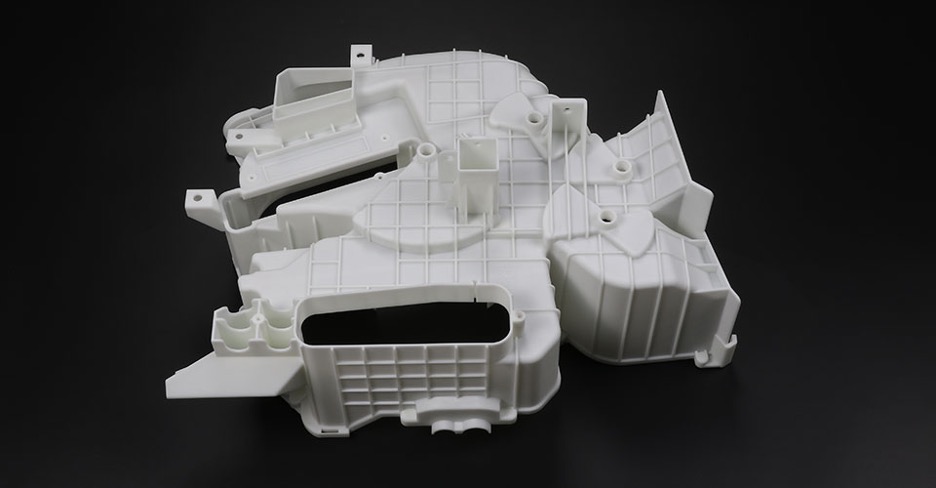

Selective Laser Sintering-SLS

Selective laser sintering (SLS) belongs to the powder bed fusion process series, which can produce high-precision and durable parts, which can be directly used for end-use, small batch production or prototype prototypes.

Advantages of SLS process:

01. SLS parts have good isotropic mechanical properties, making them ideal for functional parts and prototypes.

02. SLS does not require any support and can easily produce designs with complex geometric shapes.

03. The manufacturing capacity of SLS is very suitable for small and medium batch production.

Multi-jet Fusion (MJF)

Multi-jet fusion (MJF) is a powder bed fusion 3D printing process. In this process, the fusing agent binds powdered materials and then warms them to fuse them to generate 3D parts. MJF can print precise, long-lasting, stiff parts from Nylon PA11, PA12, and PP. They can also print TPU parts that are flexible.

Advantages of Multi-jet Fusion

01. One of the quickest 3D Printing.

02. Because of the powder bed, no support structure is required.

03. Compared to methods like SLS, it has a better surface finish and mechanical and physical properties.

Metal printing

Direct Metal Laser Sintering (DMLS) is an industrial metal 3D printing process.

Fully functional metal prototypes and production parts can be built in 7 days or less.

The final parts produced from a range of metals can be used in end-use applications.

Our metal 3D printing service

Consulting quotations and design feedback from our experienced engineering team and reliability manufacturer. There are millions of unique geometric shapes 3D printed in the past two decades.

Dedicated project management supports all your production requirements, from part design to processing.

More than 100 industrial grade metal and polymer 3D printers across five additive manufacturing technologies; Support the production projects of various engineering grade materials.

Strict process control and engineering personnel focus on achieving tight tolerances, dimensional accuracy and strong mechanical properties of parts.