Ideas are not made into products in a single day. Before it’s launched in the market, it has to undergo various stages of development. One of these stages is prototyping. It is an important step that should not be missed because it provides the developers with data on the look and feel of the final version of the product.

Prototyping is also used to test the product with a group of stakeholders. They will evaluate the prototype and the feedback will be used for further improvements in its design. It can be expensive, that’s why some developers want to skip it.

Fortunately, there is silicone molding or vacuum casting. it is an economical alternative that offers prototypes at affordable costs. With this process, product developers can have a final version of their design in low quantity.

This article will explore what silicone molding is and how it can benefit your product development process. Read it to know more.

An Introduction to Silicone Molding

Silicone molding refers to vacuum casting because this process works this way. It uses pressure inside the casting machine to eliminate the air bubbles. The master pattern is created using other manufacturing processes like 3D printing. In the process, the silicone mold is produced from the master pattern.

The history of silicone molding dates back to the 1960s in Germany. Even if the resin was developed earlier, its use in molding was developed after multiple experiments. Its use is reminiscent of the way rubber is used by restorers and sculptors.

In the silicone molding process, the material is injected inside the silicone mold. During this stage, the pressure is applied during curing inside the casting machine. The prototype has a smooth finish while the mold is reusable for multiple times without deteriorating.

Silicone molding can make small quantities of prototypes without investing too much. Since its product is used only for testing, choosing silicone molding will not be a big investment.

What Makes Silicone Molding Different

Aside from the creation of silicone molds instead of metals to produce a prototype, silicone molding differs from other molding processes because it uses a low-pressure vacuum. The vacuum machine removes the air from the material because it is sucked into the cavity. It is beneficial because the air bubbles can influence the integrity of the product.

Silicone molds are also less expensive than using metal molds. It also offers high resistance to heat, which makes it reusable even with high temperatures. But they cannot last longer than metal, hence it’s good only for low volume requirements.

Wide Range of Materials

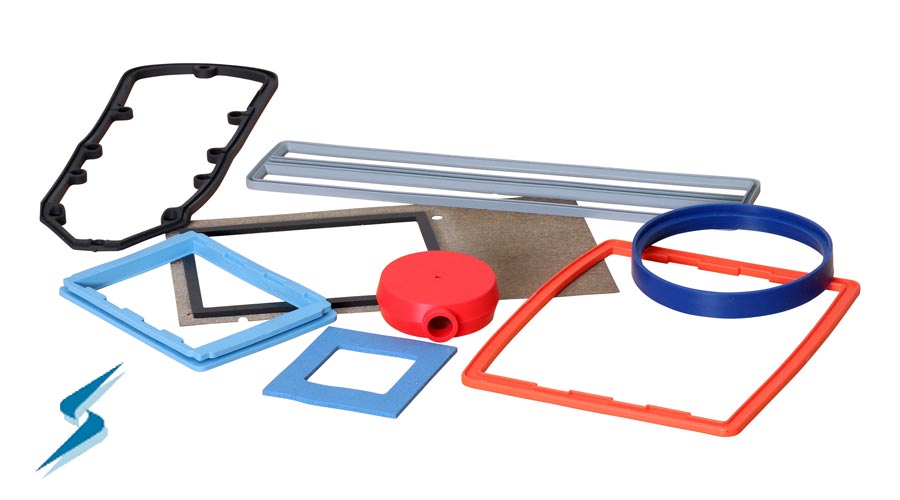

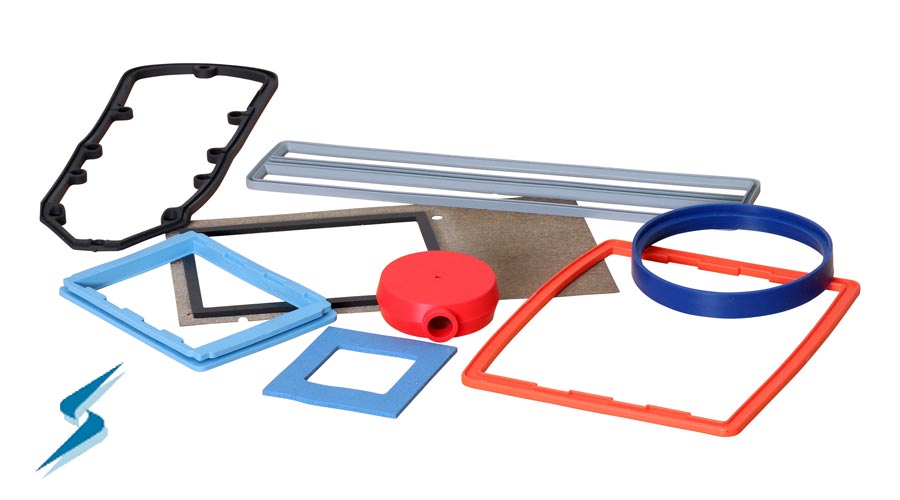

Another great benefit of using silicone molding is you can use different materials in this process that will resemble the properties of the intended product. Designers and developers can make modifications to the material based on their hardness, clarity, colors, and how it’s going to be used.

The required degree transparency of the material is also not a problem in silicone molding. You can also paint on the final part if required to resemble how the final product will look. It is also possible to have different finishes on the parts like mirror polishes or mass tinted.

It is also possible for silicone molded parts to have “over moldings” for metal inserts. You can also do “bi-molding” in this process, which means you can add one material on top of the other. All the products of silicone molding have the rigidity and flexibility, which many manufacturers are looking for.

Many Applications of Silicone Molding

The silicone molding process has many practical applications. On top of it is prototyping. It is still the most affordable and effective way of producing prototypes for product development. Aside from this, silicone molding is a great way to run a pre-series before going on mass production.

This pre-series is used for test marketing with the product’s target customers. It will help manufacturers to save on producing large quantities of new products only to find out that it does not resonate with the market. It will help the company with minimal losses in case the product is a flop.

If the new product needs certification before its launch, then silicone molding can help because it can quickly reproduce the replica of the original product. You can submit this part for testing. Again, this brings a lot of savings for the manufacturer because they can manufacture a small batch only for testing.

Products from silicone molding can preset better visual representation compared to other manufacturing processes. As such it can help the design team and the quality inspectors to make validation on the prototypes as it closely resembles the final product.

Conclusion

The silicone molding process is a great prototyping process because you can have large quantities of prototypes at a lower cost with this method. It also allows manufacturers to create products for market testing because the prototypes can be made from the same material as the final product. Welcome to contact us via enquiry@nice-rapidtooling.com to get free quote!