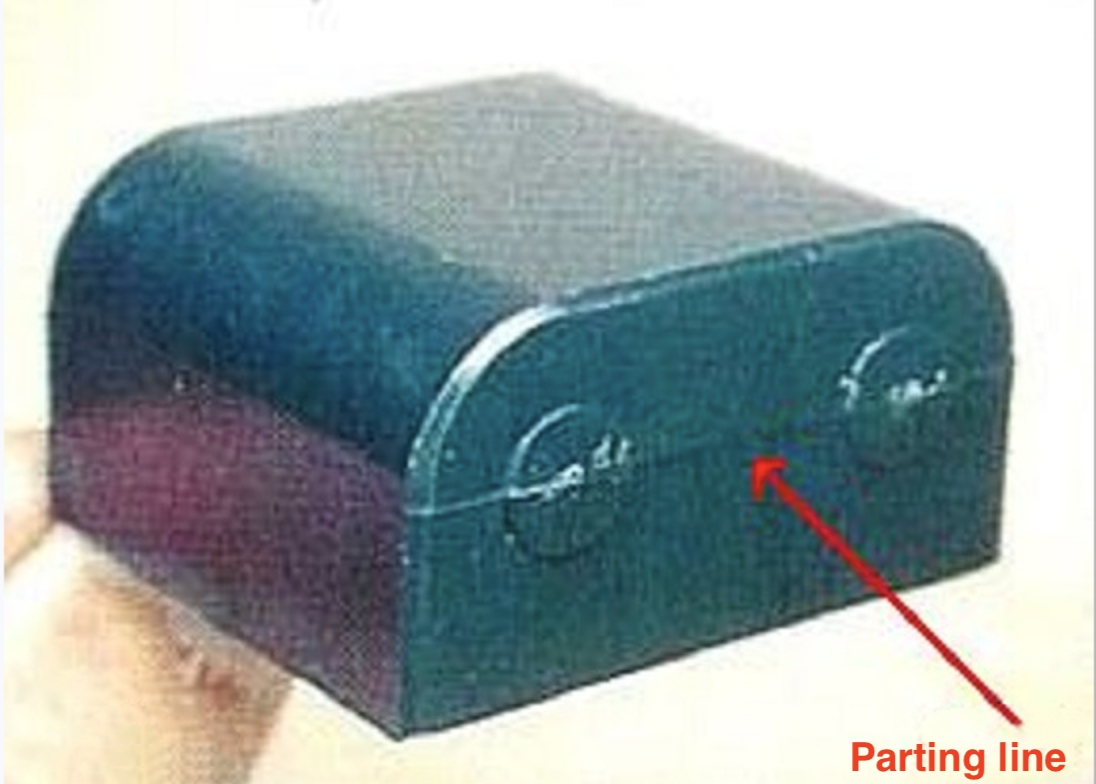

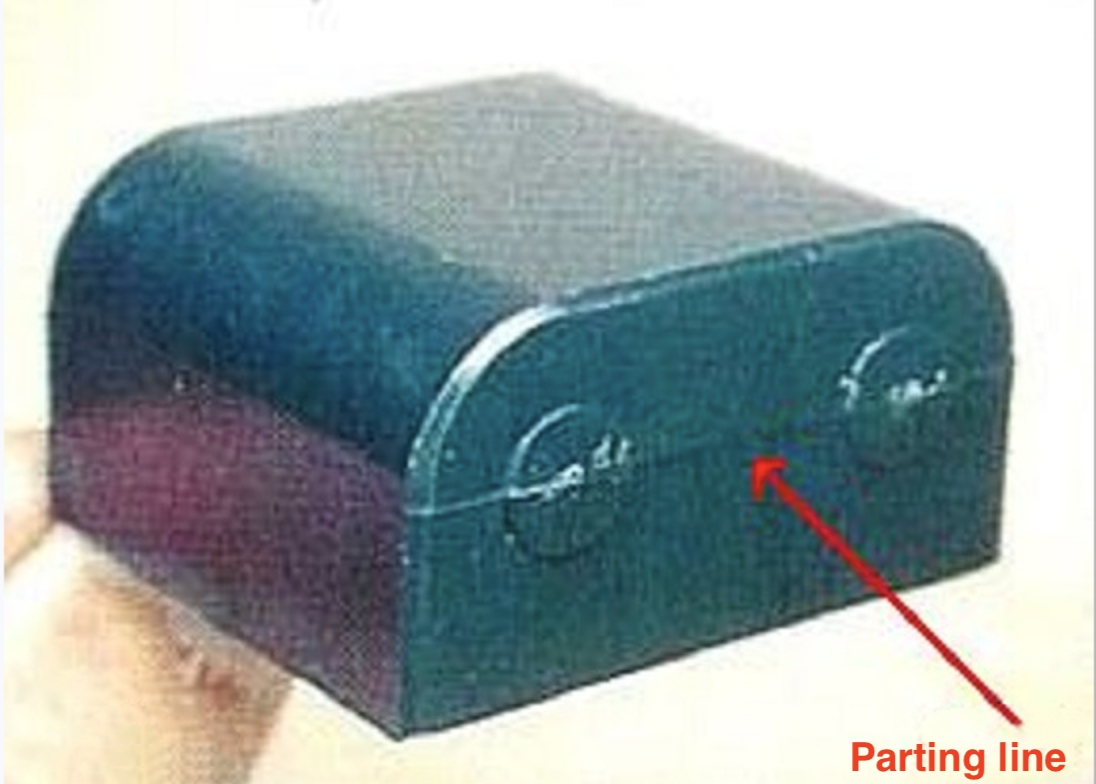

In the production process of plastic injection molding, the determination of the parting line product is very important, parting line also called the somatotype line, make some mold plastic products anyway there will be more obvious parting line mark, produces the main reason is that there is something wrong with the determination of parting line, so how do you determine product parting line?

When we determine the parting line, we must first determine the shape and position of the parting line on the plastic piece. When the die opening direction is determined, it is easier to determine the parting line. Because the projection of the parting line in the direction of die opening coincides with the external contour line of the projection of the plastic part in that direction, a straight line parallel to the direction of die opening can be used to move along the external contour line of the object projection, and the intersection of the line and the object surface at each position can be obtained.

In addition, in the two-color mold injection process, the determination of mold line is to look at the product design requirements and appearance requirements to consider whether the processing is feasible and mold placement follow up glue position, and can be divided into the following three categories:

1. If the straight line intersects the surface of the object at a point, the point is the point on the dividing line.

2. If a straight line intersects the surface of an object in a straight-line segment, any point of this straight-line segment can be used as a point on the parting line. Specifically, which point can be used as a point on the parting line is generally shortest in line with its adjacent points. It can also be determined in an interactive manner.

3. The straight line and the object intersect at multiple points and linear segments, indicating that the intersection of the global approach cone and the direction of die opening is 0, so the regional design core-pulling, mold parting line should be determined according to the shape and size of core-pulling.

Usually we will provide DFM (Design For Manufacturing) according to customer’s design after our quotation is confirmed, which can point out some issues or some defects. So if you have some ongoing plastic injection molding project or ay other, welcome to contact us by email enquiry@nice-rapidtooling.com to get free quote.