Some time ago, CNC machining was a process used mostly to create shapes and forms on metals surfaces. Time has been incredibly kind to this manufacturing technology. These days CNC machining is used to handle prototypes by using high-level upgrades capable of creating a finished, functional product in a matter of moments, and as many times as it is necessary. That is until the final result performs just as expected from the schematics for the finished product.

Rapid prototyping services have been focused on increasing precision while decreasing the role of humans during the actual manufacturing process. Every day we get to appreciate new developments for this industry released to the mass market. At the moment, we are at the peak of the possibilities, but each day a breakthrough lets us understand the untapped potential of this technology. The following are a few examples about how to use CNC machining along with plastic resins:

3D Printing Technology

There was a time when 3D printing was a rarity and something aimed at a very niche portion of the manufacturing industry. Products created using 3D printers were considered a rarity. Fast forward to 2020, and 3D printing can match the quality of any finished product created using CNC technology. The only issue needing sorting at the moment is the time it takes to build an assembled part.

To put it on layman terms, the current speed rate of performance with any 3D printer makes the tech a hot commodity, but not something that can compete with conventional CNC machining to handle large production runs right now. This obstacle will eventually be overcome, as it happened with other little setbacks, and maybe the industry will see another significant shift to something new and improved.

CNC Prototyping

3D printing is indeed perfect for tackling prototypes. But you can craft a brand new mold using a CNC prototype. This method works wonderfully to create parts that require precise tolerance rates, as well as unusual measuring, or even the use of ultra-strong polymers. CNC prototypes procedures are used for critical developments that demand complex wiring and intricate toolings such as hardware panels and control consoles.

The market is significant for sensitive technology that requires precision. A lot of these products get ongoing demand, and the brand owners are willing to work with reductions on costs to increase their supply. Since this technology rises in exposure and decreases in prices, so will the products created with it. This will lead to more offerings of rapid prototyping services.

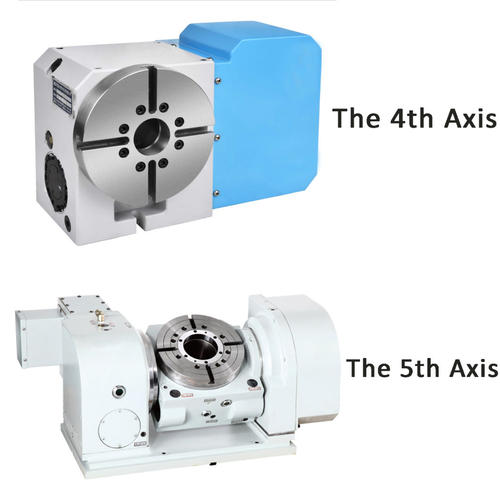

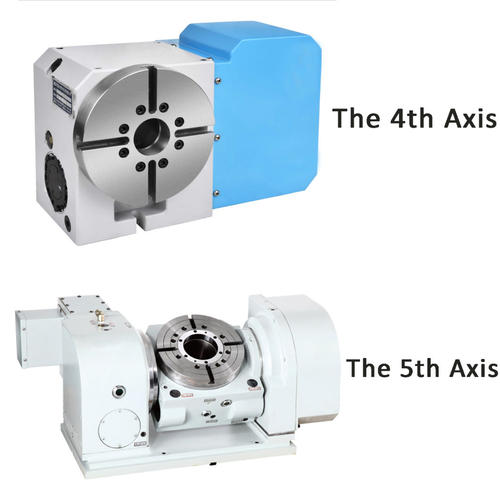

Multi-Axis Milling Tasks

The most commonly used setting to work with metals during CNC machining tasks is 3-axis cutters that offer plenty of benefits even with complex projects. To handle plastic resins, you need to turn to multi-axis technology to create new shapes. This is turn will help you to use complicated materials in raw form to create new products capable of withstanding challenging performance conditions.

The use of multi-axis technology increases the capabilities of the CNC machine. It provides CNC technology with more tools to create complex angles. Programming the device is left to the human mind. The design team and the engineering department will be the ones to come up with all the planning needed to deliver a finished product that satisfies the demands of the customer and complies with the quality conditions required.

The original article is from: https://www.nicerapid.com/does-cnc-machines-work-with-plastic-resins-a-275.html

Welcome to contact us by email enquiry@nice-rapidtooling.com if you are interested in CNC Machining or any other services, looking forward to your enquiry!