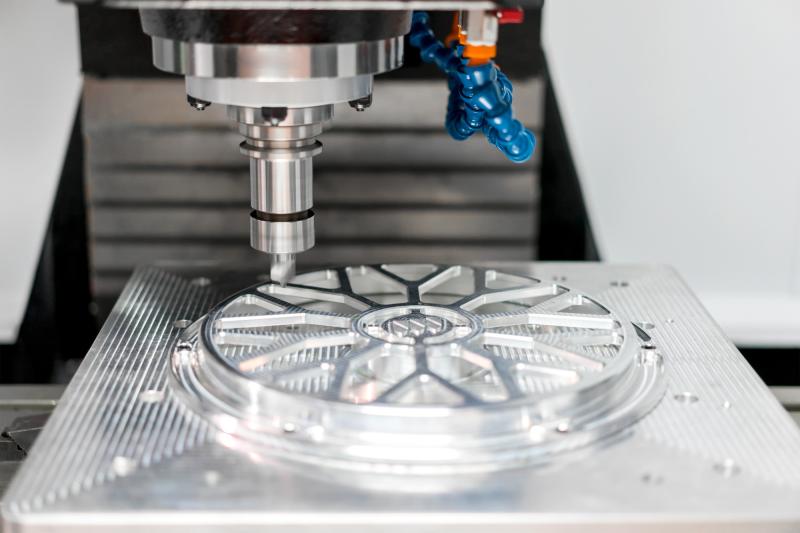

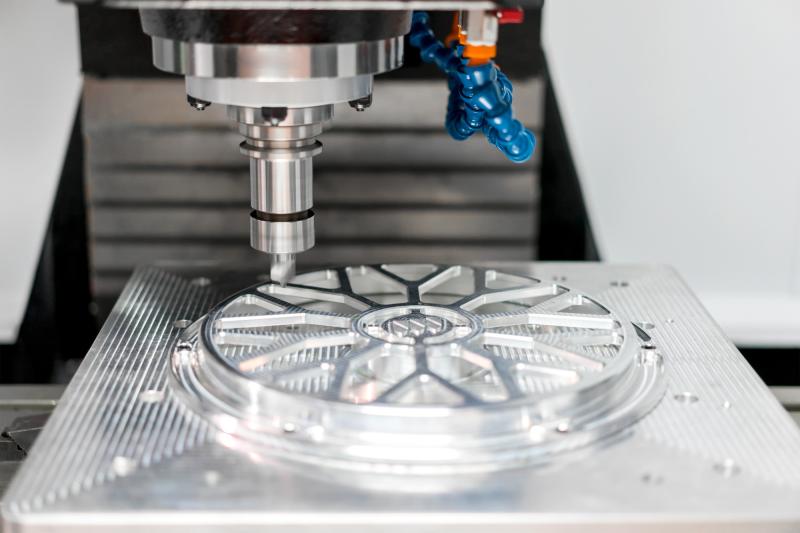

Most CNC machine operators have heard the classic mantra stating that a powerful spindle translates into a better processing effect on their CNC tasks. With better processing, you can increase your production levels, so there is no losing in such a scenario, right? The answer is not that simple, though. CNC machining is a work of precision, and as such, it requires the right tool and the correct power in the machine to accomplish all tasks.

When we are choosing the spindle motor for our CNC machine, we need to take into account the needs of the tasks we handle more frequently. If your manufacturing operation works mostly with light materials, too much power will mean a lot of wasted workpieces. This expenditure will increase the costs of production on any project, and your manufacturing operation could end up losing money. In this day and age, you can’t have that.

The Power Numbers Behind CNC Machining

Every material out there has different textures and diverse levels of hardness. You can’t possibly hope to achieve quality results on PVC with a spindle designed to cut metals. This is why it’s so important to understand that choosing the right motor for the spindle machine brings out the best performance of it, and the quality finishes desired by the client. The power of spindle motors is measured in kW (Kilowatts). Here is how it works:

Soft Materials

Soft materials such as acrylics, MDF, PVC, and other plastic usually call for a spindle powered at 1.5kW or 3.0kW. It all depends on the lightness of the workpiece. These materials are rarely heavy, so these numbers work just fine on them.

Woods

Wood is one of the trickiest materials that can be processed by CNC machines. There are just too many variations of it to list a single spindle for all of them. Lighter woods call for spindles that handle 2.5kW. Harder and more resistant woods call for a spindle motor of 4.5kW. Harder woods such as oak, lignum vitae, and apitong are used for high-end pieces of furniture. These need a powered spindle of 9kW.

Stones

Stone is probably as tricky as wood since there is a lot of diversity on the density of this material. Stone is also tough to process when it comes to shapes. Even the most potent machines can’t always achieve the desired finish, and human intervention is required to polish the finished product. The spindle power recommended for stones varies from 5.5kW to 7.5kW.

Gemstones

Gemstones are probably the most diverse field where CNC machining can do wonders. While it’s true that a machine can rarely equal the craftsmanship of an artisan, you can have amazing results using CNC making on certain gemstones. Stones such as jade or rubies can be handled by spindles powered at 2.5kW or 3.0kW. Diamonds, however, call for 9.5kW spindle motors or more.

This original article is from: https://www.nicerapid.com/quick-guide-to-choose-powerful-cnc-machining-spindle-a-328.html.

Welcome to contact us at enquiry@nice-rapidtooling.com to get free quote.