Regardless of whether it is a plastic or metal prototypes, during the processing, plastic stress will occur when the stress in the prototypes model exceeds its yield limit, especially thin, long or large and thin prototypes are more easily deformed. Hand model and real the quality of the product is still different. In the process of use, the external force, temperature, environment and other factors will cause the crack or deformation of the prototypes.

Then, what measures should we take to prevent the product from being deformed?

1. Most of the hot cracks of prototypes are caused by mechanical stress, which is caused by the solidification of the metal. The solution is to improve the structure of prototypes so that it has fewer surfaces in contact with the metal. Another method is to control the sulfur content of the metal to increase the thermal brittleness of the metal.

2.The cold crack of prototype is the crack of the product at low temperature. This is caused by the deformation of prototypes, which often occurs where rapid prototype is stretched. Cold cracks are generally small. When making large and thin parts, cold cracks often occur. Similarly, preventive measures are to reduce internal stress and control the phosphorus content of metals.

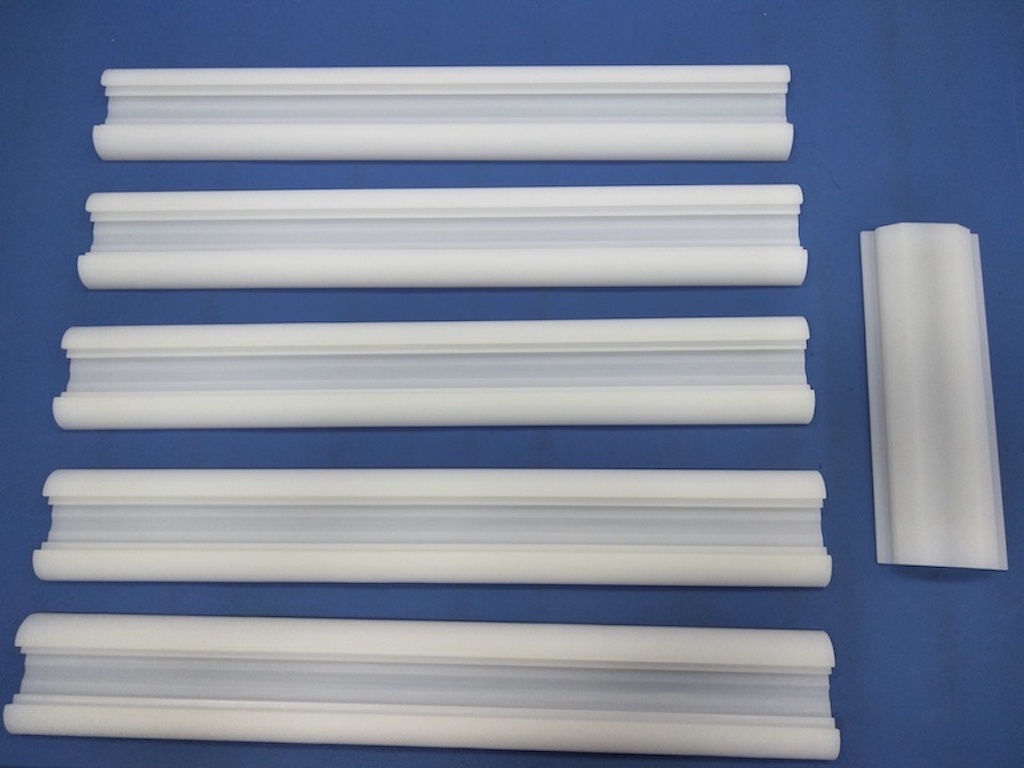

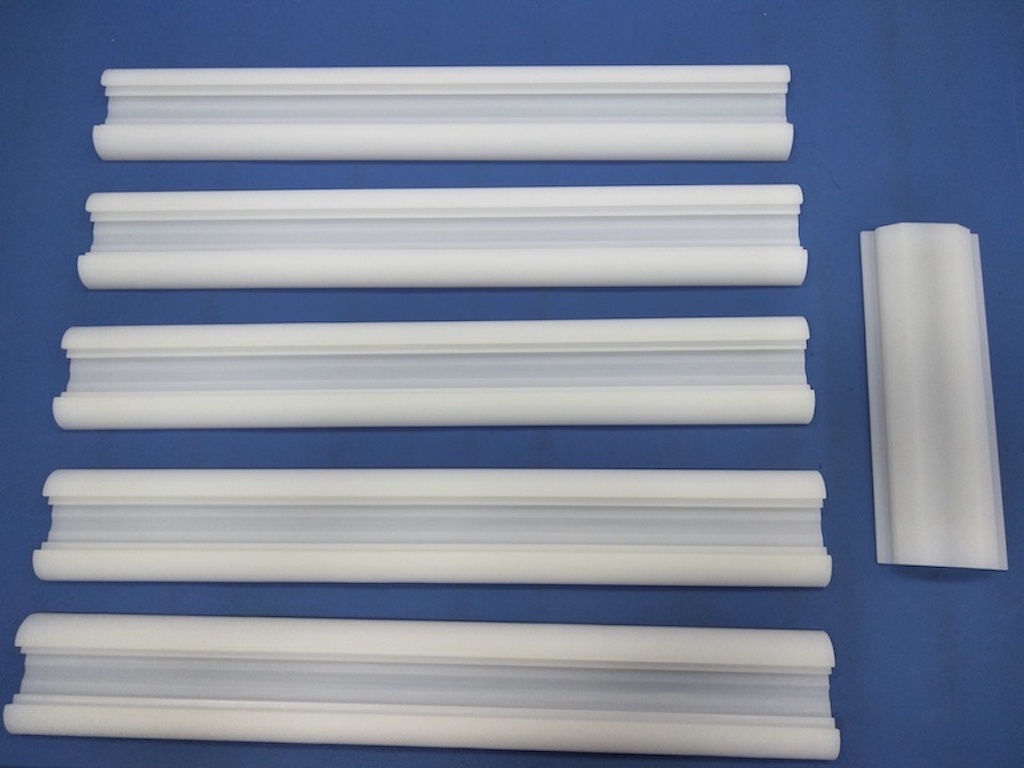

3.To prevent the deformation of prototypes, it is necessary to make the thickness of parts uniform and the shape symmetrical in the design. The method of simultaneous solidification is used in the casting process. This method reduces the internal stress of prototypes to prevent deformation. In addition, the deformation prevention measures of the long-shaped prototypes are anti-deformation measures. The principle is to eliminate the stress of the prototypes by the amount of pre-deformation that is equal in the prototypes but opposite in direction. After the parts are deformed, there is a certain residual stress in it.

To make good quality prototypes, we need technicians with lots of experience, they will deal with the balance of parts and to optimize the structure. General speaking, the thick prototypes are not easy to get deformation; the thin and big size prototypes will easy to get deformation. NiceRapid has advanced CNC Machining equipment and technicians with lots of experience, we can provide good quality products and services of rapid prototyping, rapid tooling, 3D Printing... Welcome to contact us at enquiry@nice-rapidtooling.com to get free quote.