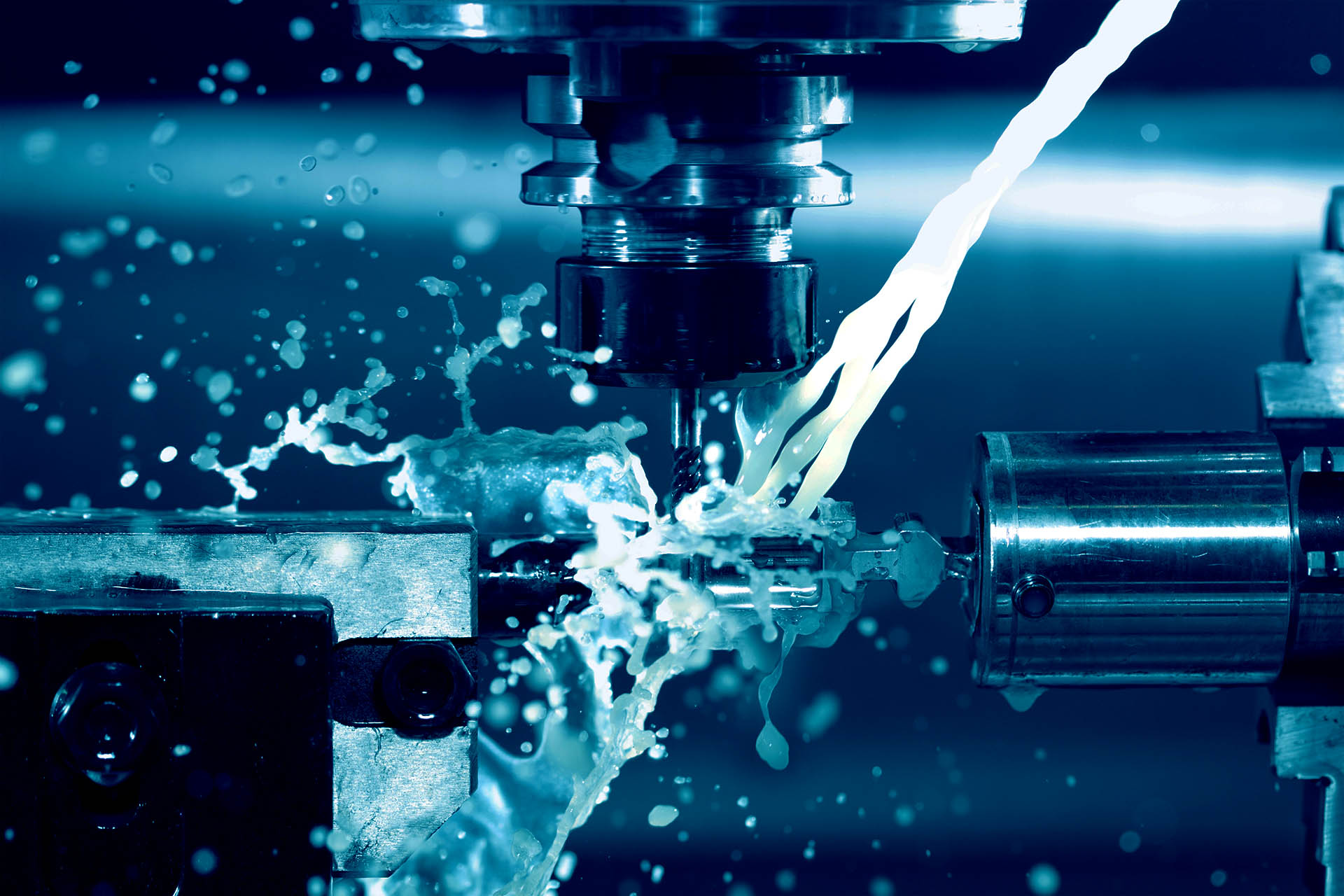

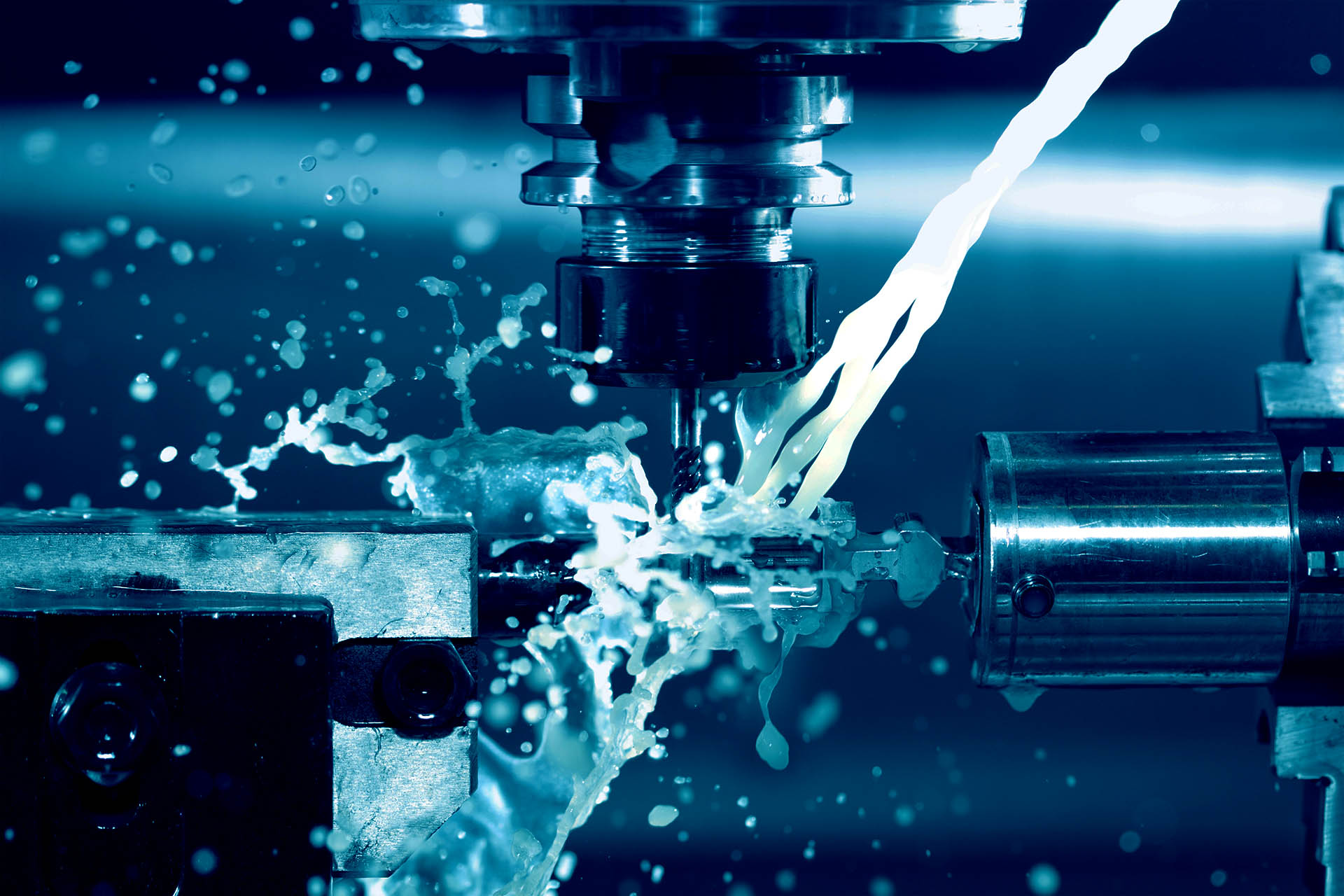

If there is one manufacturing technique that the metal industry will not survive without, it is CNC machining. Today, CNC machining is the most efficient way to handle metal fabrication tasks that are challenging with conventional means.

CNC machining is a combination of the sophistication of software programming and advancements in mechanical engineering. It leads to what we know today as “computer numerical control” or CNC.

Despite its efficiency, like any other techniques, CNC machining has its limitations. However, you can easily overcome these challenges by employing the right strategy.

Challenges in CNC Machining

1>Loss of Expertise

Before, only engineers and artisans with in-depth knowledge of metallurgy can handle complicated machining tasks. Today, we rely on machines to simplify the process and reduce the skills of the actual worker. Many people argue that the increasing ability of machines to handle difficult tasks has diminished the expertise of the people who are working in the industry.

2>Complex Geometry

In general, an average CNC machine tackles only simple designs. Expert machinists, on the other hand, can excel at what these machines cannot do. Some call its technical limitations of the machines. It is more evident in older versions that only operate in two or three axes. The newer machines, however, are slowly keeping up by offering a wider range of movements.

3>Processing of Data

The CNC machines being mechanical in nature, can operate only within the parameters of the hardware. But its performance can also be affected by the software that dictates its movement. There could be bottlenecks that may be experienced in some scenarios from the speed at which the instructions are delivered from the computer to the machines.

This can easily be overcome with an upgrade of the systems. Updating the hardware of the computer that runs the machine is the simplest solution. If it is the software, a new and more powerful version can help the machine to its full potential.

Higher Initial Cost

It is a fact that procuring a CNC machine requires significant investment, unlike buying consumables. This is more felt by startups and small companies who have no machines to upgrade from.

However, you should also note that this investment will yield profit in the long run from its many indirect benefits, like the ability to produce multiple parts and faster results.

Expensive Repairs

Since the CNC machines are expensive, you can also expect that when the machines break down, their repairs can be costly. Remember, CNC machines are made with two essential components: their hardware and software. When any of these components experience a breakdown, it will need the expertise of a computer programmer and an engineer to repair.

As a preventive measure, CNC machines must be under a reliable preventive maintenance program. It also requires regular checks on both hardware and software to avoid unnecessary stoppage on its operation.

The original article is from: https://www.nicerapid.com/overcoming-the-top-challenges-in-cnc-machining-a-535.html

Summary

As you can see, there are limitations to CNC machining. But knowing these potential issues can help you overcome them. We advise you to keep this information in mind, and you can ensure that your CNC machines will run smoothly and efficiently. Don't hesitate to contact us via email enquiry@nice-rapidtooling.com if you get any other questions, we looking forward to your enquiry!