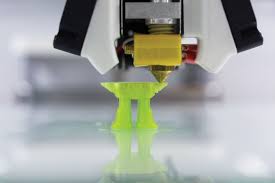

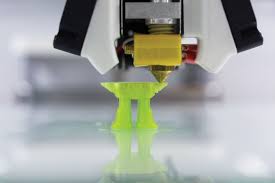

FDM Technology is developed by Scott Crump, co-founder of Stratasys in 1988. An FDM printer uses a thermoplastic polymer in a filament form to create three-dimensional object. It is the most widely used type of 3D Printing at the consumer level.

FDM Technology works with specialized 3D printers and production-grade thermoplastics to build strong, durable and dimensionally stable parts with the best accuracy and repeatability of any 3D printing technology. FDM 3D printers are well-suited for basic proof-of-concept models, as well as quick and low-cost prototyping of simple parts, such as parts that might typically be machined.

When additive manufacturing process produce parts layer by layer, each layer also introduces an opportunity for inaccuracy. The process by which layers are formed affects the surface quality, level of precision and the accuracy of each layer, and consequently, the overall print quality.

FDM 3D Printers form layers depositing lines of molten material. With this process, the resolution of the part is defined by the size of the extrusion nozzle and there are voids in between the rounded lines as the nozzle deposits them. As a result, layers may not fully adhere to one another, layers are generally clearly visible on the surface, and the process lacks the ability to reproduce intricate details that other technologies can offer.

What’s material are available by FDM?

FDM Technology uses the same tried and tested thermoplastic found in traditional manufacturing processes. For applications that demand tight tolerance, toughness and environmental stability-or specialized properties like electrostatic dissipation, translucence, biocompatibility, V0 flammability or FST ratings—there’s and FDM thermoplastic that can deliver.

Some benefits of FDM

*The technology is clean, simple-to us and office -friendly.

*Supported production-grade thermoplastic are mechanically and environmentally stable.

*Complex geometries and cavities that would otherwise be problematic become practical with FDM technology.

Then, when to use FDM? It should be rapid prototyping, building low-cost models, great for hobbyists and makers, when precision and surface finish isn’t crucial.

If you have to choose one or the other ask yourself if you need a more robust part printed in more common materials, or if you need a highly detailed part that looks nice. If you need a stronger, usable part, an FDM printer might be the way to go, but if you just need a nice looking, detailed part, the SLA printer might be your choice. Either way, 3D Printing is a great way to quickly take a digital design and make it a physical reality. Contact us via enquiry@nice-rapidtooling.com if you are interested.