3D printing or as it's popularly known additive manufacturing is one of the most effective and efficient techniques when it comes to the manufacture of consumer goods. 3D printing dates back to the 1980s when it was used to make prototypes.

As technology continues to change, firms have adopted different 3D printing technologies to meet their needs and requirements. Among different techniques used in 3D printing, one of the most popular is Fused Deposition Modeling (FDM).

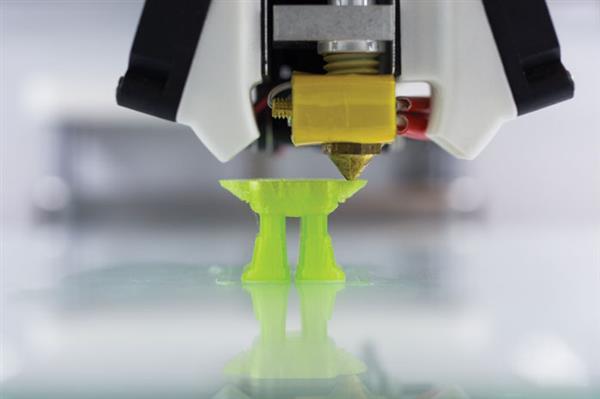

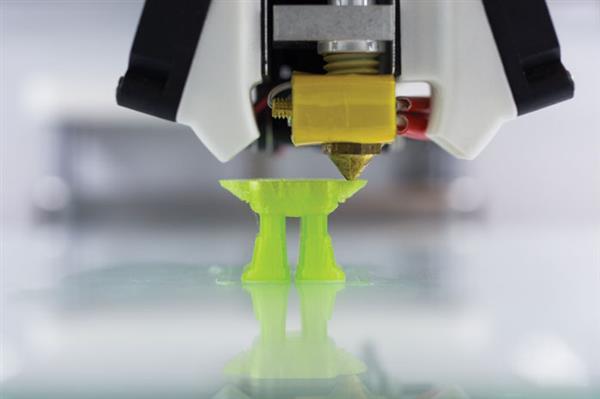

FDM 3D printing exerts both horizontally and vertically whereby the extracted nozzle proceeds above the erect program. FDM uses a thermoplastic filament that heats up and converted into a melted substance which is then ejected slowly layer by layer creating a 3-dimensional part and product.

How does FDM 3D printing works?

Just like any other type of 3D printing, Fused Deposition Modeling utilizes a digital outline that is transferred onto a 3D printer. With FDM 3D printing, it utilizes a wide variety of polymers such as PLA, ABS, PETG, PEI, and PEEK.

First and foremost, the printer holds all the plastic threads which are sucked from the loop using a nozzle.

The fibers are liquefied and inserted downwards onto the table that has a base and nozzle. The data processor exertion by interpreting the substance and its proportion towards the focal that assemble it viable for the nozzle and bottom to accompany.

Simultaneously, the nozzle will pass over the base and the plastic crisp making it rigid which creates a dense pledge on the preceding layer. The printing head moves upwards in sequence following the layer where plastic is deposited.

Through the use of 3D printing, it will create parts and products basing on its dimensions allowing for the rapid manufacture of desired prototypes or products within the shortest time possible.

What is FDM 3D printing mainly used for?

The FDM 3D printing techniques have gained popularity over recent years owing to their efficiency as well as low-printing cost. FDM is used in a wide array of industries ranging from consumer goods, automobiles as well as sports gadgets and equipment's just to mention a few.

Future of FDM 3D printing

The use and capacity of FDM 3D printing are increasing by the day, a lot of firms and workshops are now incorporating it as the go-to 3D printing technique owing to the benefits that it brings to a business.

The sky is the limit, FDM 3D printing is quite more manageable compared to other printing techniques thus ensuring your business will remain ahead of the market curve as you'll be able to deliver all your products on time ensuring your clients never have shortages.

This printing technique is the simple, cost-effective, and compact meaning you'll be getting the best manufacturing that there is in the market especially when it comes to 3D printing.

The original article is from: https://www.nicerapid.com/what-is-fused-deposition-modeling-a-516.html

Welcome to contact us via enquiry@nice-rapidtooling.com to get free quote!