Almost every manufacturing industry, from automobile production plants to manufacturing musical instruments, uilizses computer number control machines. As a manufacturer, you must be familar with CNC machining and how it can benefit your business in manfacturing operations.

Advanced machines and Operations of CNC Machining

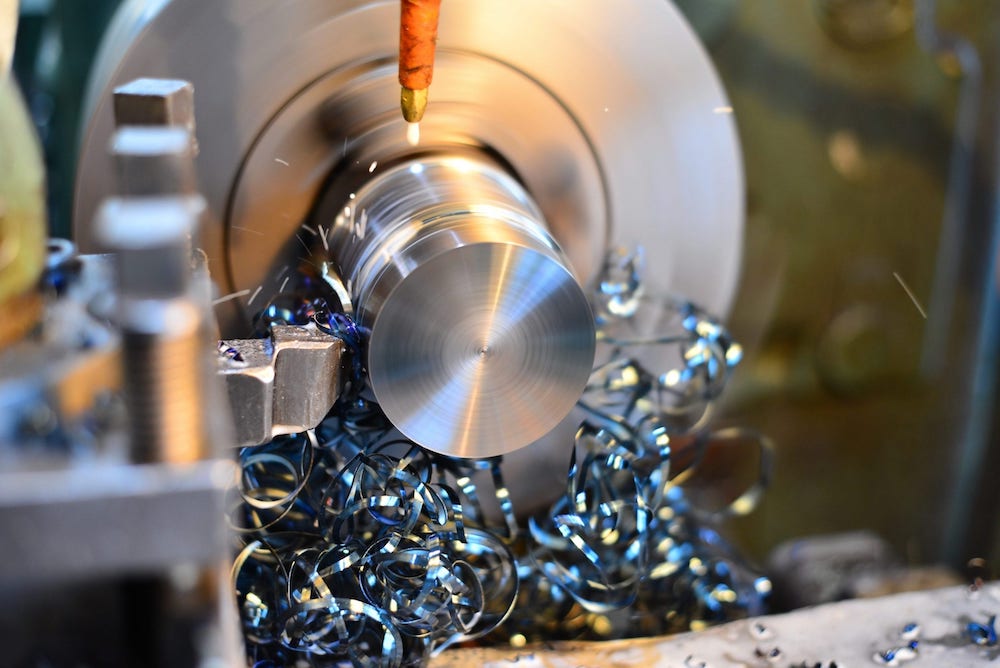

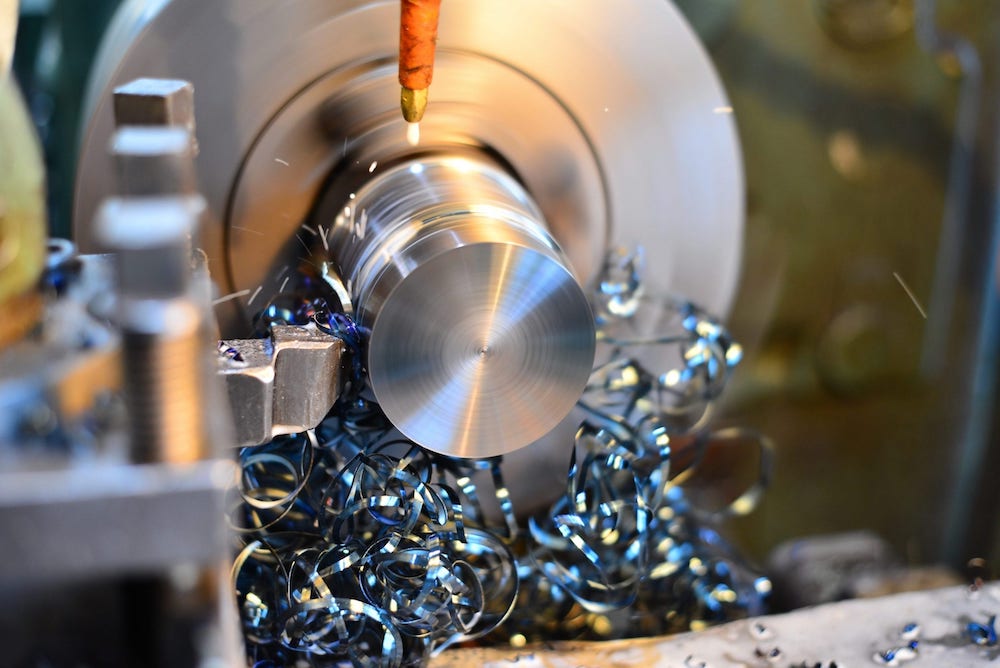

CNC Machining is a manufacturing approach dictated by predefined computer codes that guide the functioning of machinery like a grinder, milling, or lathe. It offers multiple features such as multi-axis capabilities (3-axis, 4-axis, 5-axis) and computer control. For instance, a CNC lathe can operate diversely by doing cuts in circular directions. And some parts can get right angle by using EDM or wire cutting processes. Meanwhile, production in the automotive industry relies heavily on CNC machining due to the demand for parts and the need for higher precision. Therefore, the current trend of CNC machining brings great hope for the machine shop.

Advantages of CNC Machining

CNC Machining has lots of advantages in manufacturing production, and the most prominent advantage these machines offer is their ability to perform multiple operations continuously without changing the Settings, reducing the possibility of errors due to human intervention.

1. Reduced labor

CNC machining requires less labor to complete production tasks. A skilled operator can operate most of the autonomous CNC machines, and a programmer can get them to load the required designs. Savings in human resources can be passed on to customers, giving you a competitive advantage.

2. Multiple Capability

When integrated with advanced design software, CNC machine tools produce output that cannot be replicated by manual machines. CNC machines can produce parts of the required size, shape, or texture. Best of all, an efficient bench-top CNC milling machine can produce maximum performance while taking up minimum space.

The wide use of CNC machines in multiple industries optimizes a wide range of manufacturing capabilities. It ensures extremely high accuracy, cost effectiveness, safety of equipment, and enables mass production of parts.

With the spread of industrial automation, CNC machining and tools are helping to reduce costs and speed up the pace of production. CNC machining enables enterprises large and small to have a greater competitive advantage, and provides greater work flexibility and a wide selection of materials.Welcome to contact us via email enquiry@nice-rapidtooling.com to get free quote!